Aluminum is a common alloy that is used for the production of various elements such as utensils, tools, machinery, etc. Aluminum comes in many forms and everyone has a different composition and texture to it.

Most found aluminum is of two types known as aluminum 6061 vs 7075. Both these types have some differences in them and are used in the manufacturing of different kinds of materials. Let us take a look at the most common difference between the aluminum 6061 vs 7075.Aluminum 6061 is formed by hardening aluminum alloy after the process of precipitation. It contains magnesium and silicon in its composition. It’s also known as the “Alloy 61S”

Aluminum 7075 is formed by using zinc as the primary alloying element. It has copper and magnesium as well in its composition in addition to zinc. It was first founded secretly by a Japanese company. To know the differences between both these aluminum alloys, let us take a look at the difference between them

Differences between aluminum 6061 and 7075:

Composition:

Aluminum 6061 and aluminum 7075 have differences in their composition. The aluminum 6061 has magnesium and silicon as its main composition elements. Aluminum 6061 is generally used as a purpose element while aluminum 7075 is a strong element and has a hard composition including zinc as its primary alloying element.

Features:

The main features that are present in the aluminum 6061 are that it is a good corrosion-resistant alloy and can be wielded effectively as well as it also has good machinability properties. On the other hand, aluminum 7075 is a story alloy and has a perfect ratio between its strength and weight.

Uses:

Aluminum 6061 is the most common general alloy. It is widely used in building components and materials for architectural and structural work. It is widely used in electrical machinery for the production of various components.

They are also used to make marine fittings. However, as the aluminum 7075 are stronger in composition than the 6061 so this alloy is widely used in making defense elements and weapons as well as used in aerospace technology development. They play an important role in the manufacturing of automobile parts and also sports equipment.

Mechanical properties:

The aluminum 6061 alloy is soft and easily bendable material. A person can easily work with aluminum 6061 as it can be converted to any desired form or shape however on the contrary as we already know that aluminum 7075 is a hard alloy.

Its texture is also brittle due to crystal formation on its surface. It’s also a bit difficult to work with aluminum 7075 as it can’t be wielded easily and has a lower ratio of formability.

Machinability:

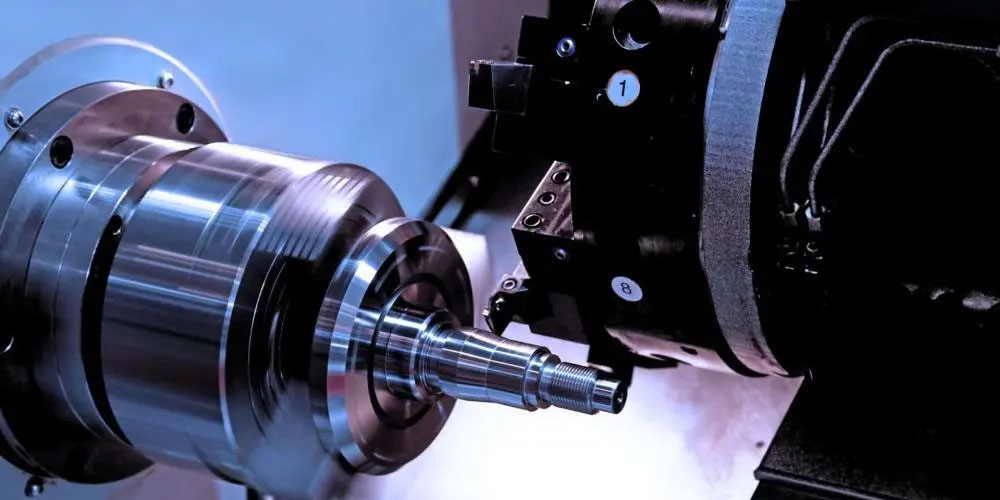

It is the process of the formation of different products from an alloy. As aluminum 6061 is a soft alloy it has high machinability properties and can be easily molded and converted into desired products and so is a commonly used alloy while aluminum 7075 due to its hard composition has a lower machinability property and hence takes a lot of time and more hard work to convert it into the desired product

Conclusion:

Both the alloys, aluminum 6061 and aluminum 7075 have their separate compositions and can be used accordingly to their features and composition in the making of various products and be used in everyday life.